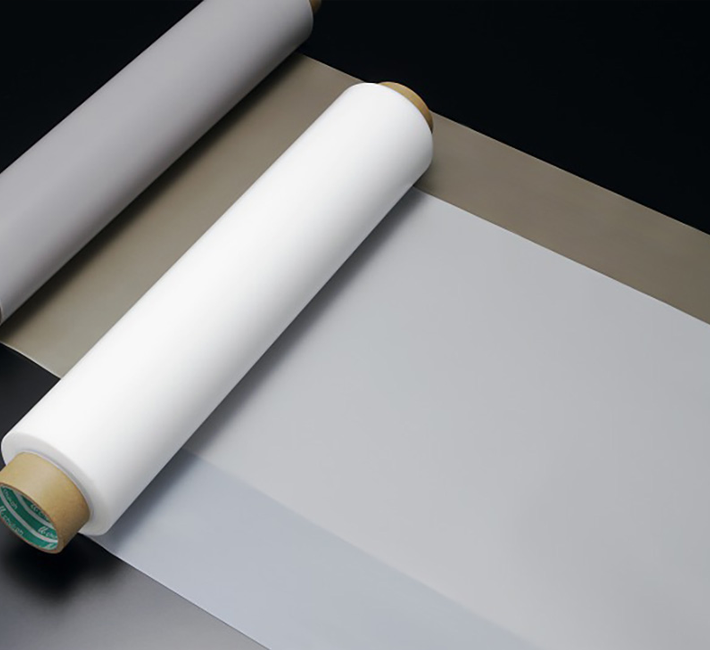

The PTFE film is treated with a special surface and then coated with

a special silicone adhesive to make a high temperature resistant

PTFE film tape. Has a wide operating temperature range.

The coefficient of friction is small and the substrate has good

sliding properties. Has excellent water resistance, solvent

resistance, and voltage resistance. The adhesive uses heat-resistant

silicone, which can be cleanly removed even after heating.

Electrical insulation, heat resistance, weather resistance, chemical

resistance, mold release resistance, abrasion resistance, flame retardancy

The products are widely used in conductive rollers, and have the advantages

of high temperature resistance, acid resistance, alkali resistance,

non-contamination of the surface, low friction on the heating surface,

plastic mold pull-off, high-temperature and high-voltage cable connection,

binding, anti-static and other advantages. It protects the high-temperature

welding of electrical components and the pasting of thermoplastic parts.

Easy to use, long life and good insulation performance. The applicable

temperature range of the tape is -60℃~260℃

| UL-H level standard (180℃) |

| Substrate: PTFE film/Polytetrafluoroethylene film |

| Adhesive: Silicone-based |

| Low coefficient of friction, so it has excellent substrate sliding

properties |

| Good corrosion resistance, anti-corrosion sealing of petrochemical pipeline |

| Demoulding of wind turbine blades, demoulding applications of composite

materials for aircraft parts and auto parts |

| PTFE pure film tape, gray, white, antistatic, etc. customized |